-

Meet various requirements• Different coolers available for light weight, low power, long operation life

• Long range, non-contact, high efficient and high reliability

• Guarantee secure and wide range of gas leak detection -

High sensitivity• Quite efficient in application of low gas concentration and slow gas flow

• Effective leak detection includes Alkanes, Alkenes, Alcohols, Benzenes, Ketones and other gases

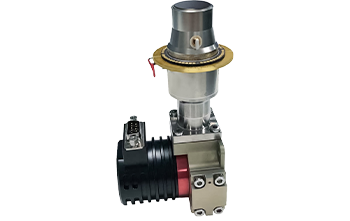

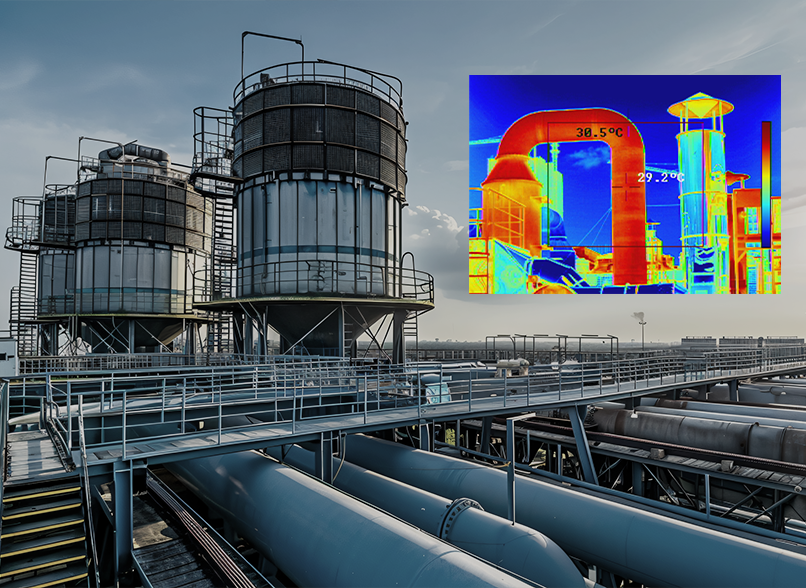

The cooled infrared detectors for optical gas imaging (OGI) are specially developed for gas leak detection with the function of converting infrared radiation of target with medium and long wavelength into electrical signal. Its external mechanical interface, optical interface and electronic interface are commonly used and can be expanded. They can be widely used in environment monitoring, gas leakage detection, pollutant discharge, chemical gas detection in petrochemical plants and refineries.

Utilizing cutting-edge MCT (Mercury Cadmium Telluride) and Type II Superlattice (T2SL) sensitive materials, these detectors offer unparalleled sensitivity and accuracy for a variety of gas leak detection applications. The advantages of both MCT and T2SL materials ensure high performance across a diverse range of infrared wavelengths and results in exceptional sensitivity to target gases, allowing for accurate leak detection even at low concentrations, so that real-time visual presentations of gas leaks can be provided to enable quick assessment and response.

There are various applications that are ideal for a wide ranges of gas detection scenarios, including:

- Identification of volatile organic compounds (VOCs) in petrochemical environments, ensuring compliance and safety.

- Reliable monitoring of CO gas leak in various industrial settings, safeguarding personnel and equipment.

- Various industrial waste gas emissions in heating furnaces and kilns with extreme temperature environments.

- SF6/NH gas detection in various industrial applications, specifically sulfur hexafluoride (SF6) and ammonia (NH3) gases.

| Model | G330Z3 | G615Z3 | G330Z6 | G330Z5 | G330C2 | |

| Applications | VOCs Petrochemical Gas Detection | CO Gas Detection | High Temperature Industrial Heating Furnace | SF./NH Gas Detection | ||

| Sensitive Material | MCT | T2SL | ||||

| Resolution | 320×256 | 640×512 | 320×256 | |||

| Pixel Size | 30μm | 15μm | 30μm | |||

| Spectral Response | 3.2±0.1μm~3.5μm±0.1μm | 4.5±0.1μm~4.7μm±0.1μm | 3.8±0.1μm~4.1μm±0.1μm | 10.3±0.1μm~10.9μm±0.1μm | ||

| Typical NETD | 10mk (F1.5) | 20mk (F1.5) | 10mk (F1.5) | 20mk (F1.5) | ||

| Effective Pixel Rate | ≥99.5% | ≥99.76% | ≥99.5% | |||

| Response Non-uniformity | ≤8% | |||||

| Cryocooler | RC3 | LC2 | RC3 | RC3 | RC3 | RC4 |

Steady Power Consumption | ≤7W | ≤5.5W | ≤7.5W | ≤7.5W | ≤7.5W | ≤10W |

| Max. Power Consumption | ≤15W | ≤14.5W | ≤13W | ≤13W | ≤13W | ≤18W |

| Power Supply | 12V DC | 24V DC | ||||

| Cooling Time | ≤7min | ≤5min | ≤7min | |||

| Size (mm) | 142×58.5×71 | 33.5×86×68 | 142×58.5×71 | |||

| Weight | ≤600g | ≤300g | ≤600g | |||

| Working Temperature | -45℃~+71℃ | |||||