-

Meet various integration requirements• Different product forms, rotary/split/miniaturized

• Fast cooling, high flexibility and reliability -

Long working time• Meet 7*24H long-time operation

• MTTF up to 25,000 hours

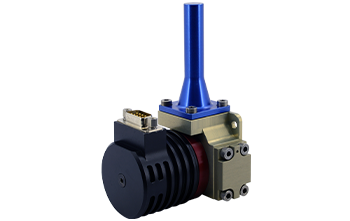

Cryocooler is an indispensable part of cooled infrared detector. It provides a cryogenic working environment for the focal plane array and ensures the normal operation of cooled infrared detectors. The Integrate Dewar Cooler Assembly (IDCA) is implemented to achieve compactness and efficiency. The cryocooler provides a versatile and efficient cooling solution designed to match all kinds of cooled IR detectors. Available in rotary and linear types, our cryocoolers suit your specific application and installation requirements and offer flexibility and reliability for a wide range of infrared detection applications. The cryocoolers are designed to seamlessly integrate with various cooled IR detectors, ensuring optimal performance and extended detector lifespan.

The rotary crycooler adopts key technologies such as high-efficiency brushless DC motor drive, high-efficiency wear-resistant coating, and high-precision miniature bearing support. It has compact structure, small size, light weight and can adapt to various harsh environments. It is widely used in various electro-optical systems, handheld imagers, pods, turrets, security camera etc.

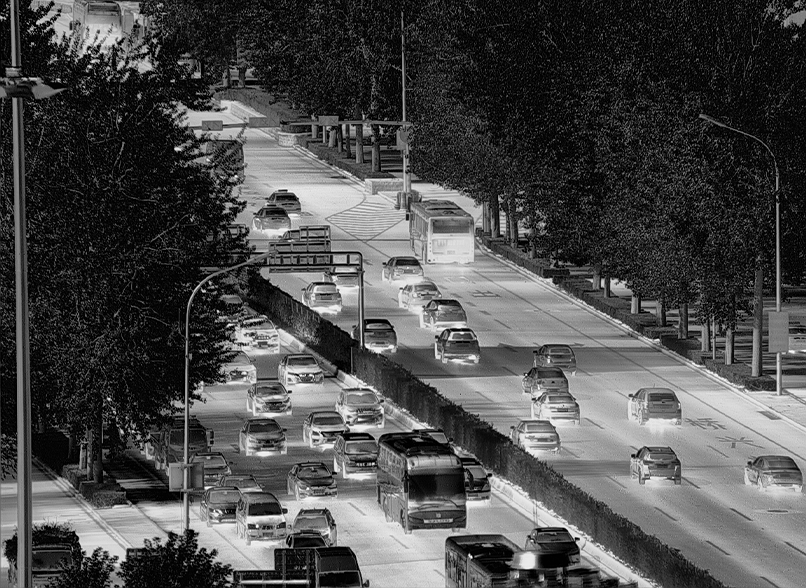

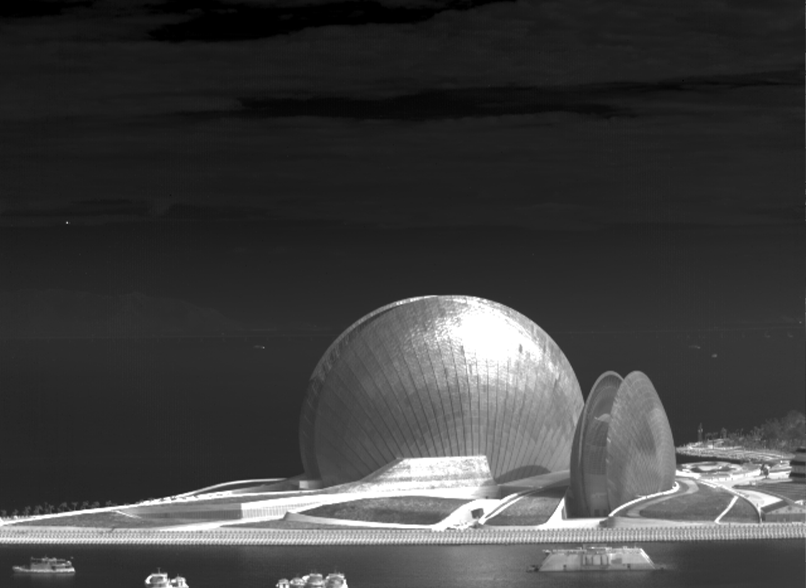

While the linear cryocooler adopts high efficiency moving-magnet linear motor drive, symmetrical compression piston and external coil. It has characteristics of fast cooling, wide operating temperature range, low vibration, low noise and high reliability, meeting the needs of 7*24H long-time operation. It can be used in applications such as Gas Leak Monitoring, Security Monitoring and other scenarios that require long-term operation.

| Type | Rotary Stirling Cooler | Linear Split Stirling Cooler | ||

| Model | RC1 | RC2 | RC6 | LC4 |

| Cooling Power | ≥400mW (@77K@20℃) | ≥550mW (@77K@20℃) | ≥750mW (@77K@20℃) | ≥1300mW (@77K@20℃) |

| Input Voltage | 24-32VDC/9-12VDC | 18-28VDC/12-16VDC | 18-28VDC | 24DC |

| Max. Power Consumption (71℃) | ≤12W | ≤14W | ≤24W | ≤50W |

| Steady Power Consumption (23℃) | ≤4.5W (130mW@77K@20℃) | ≤5.5W (220mW@77K@20℃) | ≤12W (550mW@77K@20℃) | ≤10W (430mW@77K@20℃) |

| Cooling Time (23℃) | ≤5min (150J@77K@20℃) | ≤5min (250J@77K@20℃) | ≤5min (500J@77K@20℃) | ≤4min (450J@77K@20℃) |

| Cold Finger Size | Φ6.4mm | Φ8mm | Φ9.4mm | Φ8mm |

| Max. Size (mm) | 99×81.5×46.5 | 116×58.5×71 | 120×59×78 | Compressor Φ46×122 Expander Φ40×88 |

| Weight | ≤260g | ≤430g | ≤500g | ≤1000g |

| Working Temperature | -45℃~+71℃ | -45℃~+71℃ | -45℃~+71℃ | -45℃~71℃ |

| Storage Temperature | -55℃~+85℃ | -55℃~+85℃ | -55℃~+85℃ | -55℃~+85℃ |

| Electronic Control Drive | External | Built-in | Built-in | External |

| Coupling Method | IDDCA | |||

| MTTF | ≥10000h | ≥10000h | ≥10000h | ≥25000h |